3D Embroidery, Silicone Print, Patchwork – What’s Trending Now?

- Share

- publisher

- 88

- Issue Time

- Jul 9,2025

Summary

3D embroidery (0.5-3mm), silicone prints (0.5-1.2mm) & patchwork redefine streetwear: 210% 3D growth, 37% cheaper silicone, 76% celeb adoption. Includes cost tools & supplier tips.

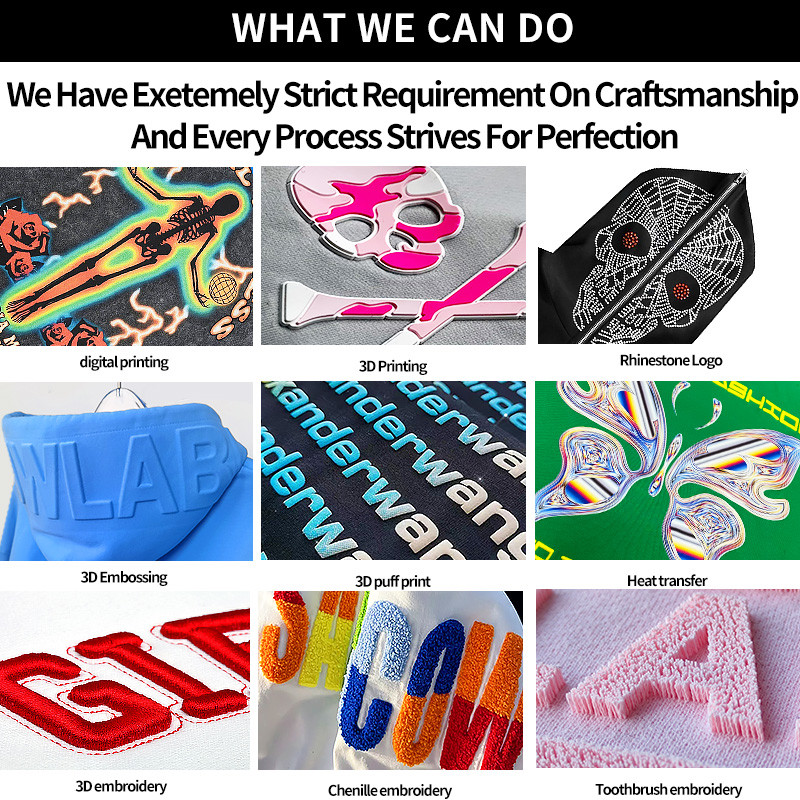

In today's fiercely competitive streetwear market, craftsmanship details have become the ultimate weapon for brand differentiation. From the strikingly dimensional 3D embroidery, to the uniquely textured silicone printing, and the eco-chic patchwork design, these innovative techniques are redefining the value proposition of streetwear. We'll provide an in-depth analysis of their core characteristics, market performance, and real production data to help your brand gain a competitive edge.

In this article, we will delve into the differences among the three processes, and explore how to make rational choices among these processes in a changing environment to achieve maximum benefits.

1.3D Embroidery: The Luxury Craft That Makes Logos "Pop"

Essence: Tactile Dimension & Precision Craftsmanship

Utilizing German Amann Serafil threads with 0.3mm padding through multi-layer stitching, 3D embroidery creates bas-relief effects that deliver far greater visual impact than traditional flat embroidery.

Key Production Insights

✅ Cost & Premium Potential:

4-6x higher unit cost than standard embroidery (premium pieces: ¥50-80/unit)

Commands up to 300% market premium (e.g., Vlone's 3D rose logo hoodies at ¥2000+)

✅ Technical Specifications:

Requires ≥8000 stitches/cm² density (for optimal dimensionality)

Recommended equipment: Tajima TMAR-KC multi-head machines (+40% efficiency)

✅ Cutting-Edge Innovations:

"Floating Embroidery" (Japanese technology): Special backing creates suspended effect, enhancing dimensionality by 40%

Luminous threads: 8-hour glow after light exposure (perfect for limited editions)

Ideal Brand Positioning:

Premium streetwear (¥1000+ price points emphasizing craftsmanship)

Collaborations/limited editions (enhancing collectibility through 3D effects)

Benchmark Cases:

Fear of God's 3D letter-embroidered hoodies (perennial bestsellers)

Ambush's dimensional bear logo (high social media visibility)

2.Silicone Printing: The Ultimate Weapon in Tactile Economy

Core Technique: Skin-Like Texture + Durability

Silicone printing utilizes liquid silicone (0.5-1.2mm thickness) for precision printing, creating an elastic matte coating that offers superior softness and wash resistance (2024 TPU materials achieve 100 machine washes without degradation).

Key Production Data

✅ Cost vs. Premium Pricing:

2-3x higher unit cost than traditional plastisol printing (~¥15-25/piece)

Consumers willingly pay 80-120% more for the "tactile experience" (e.g., Gallery Dept.'s silicone slogan tees sell for ¥1500+)

✅ Technical Requirements:

Must use 200+ mesh high-precision screens

Curing temperature strictly controlled at 160°C±5° (critical for elasticity)

Recommended equipment: Rotex thermosetting silicone printers (Italy)

✅ Cutting-Edge Tech:

Thermochromic silicone: Color shifts at 32°C (patented by Supreme collabs)

Micro-porous breathable tech: 300% better airflow while remaining waterproof

Glow-in-the-dark silicone: 12-hour luminosity after charging

Ideal For:

Premium street brands (¥600-1500 range emphasizing tactile luxury)

Special collaborations (functional silicone creates buzz)

Case Studies:

Balenciaga's thermosensitive logo hoodies (sparked social media challenges)

Gallery Dept.'s distressed tees with thick silicone slogans (400% resale premium)

3.Deconstructed Patchwork: The Advanced Playbook for Sustainable Fashion

Core Technique: Zero-Waste + Unique Aesthetic

Patchwork craftsmanship utilizes high-precision laser cutting (≤0.3mm tolerance) to repurpose 3-5 types of deadstock fabrics, combined with seamless heat-sealing technology to create one-of-a-kind pieces with 92% material utilization (vs. just 65% in traditional methods).

Key Production Data

✅ Cost vs. Premium Pricing:

40-60% lower material costs (using deadstock fabrics)

Commands 150-200% market premium (e.g., Vivienne Westwood patchwork jackets resell for 8x retail)

Only 3.5% production waste (vs. 15-20% for traditional patchwork)

✅ Technical Requirements:

Must use TRUMPF TruLaser 3030 cutting systems

Requires 3-stage temperature control for bonding (80°C/120°C/160°C gradient curing)

Colorfastness must meet ISO 105-C06 Level 4+ standards

✅ Cutting-Edge Tech:

AI Patchwork System: Auto-generates optimal layout (saves 27% labor time)

Reversible Patchwork: Special adhesive allows disassembly/reassembly (Marine Serre patent)

Thermochromic Patchwork: Color-shifting with ambient temperature

Ideal For:

Eco-conscious brands (emphasizing sustainability)

Designer labels (creating art-level pieces)

Celebrity collaborations (leveraging "exclusivity" as key selling point)

Case Studies:

Martine Rose: Reconstructed 17 types of denim deadstock into hit jackets

Vivienne Westwood: Patchwork statement pieces auctioned at 8x retail value

Final Thoughts

These three techniques are reshaping streetwear's value chain—3D embroidery builds visual memorability, silicone printing creates tactile addiction, and patchwork tells sustainable stories. When Gen Z consumers willingly pay premiums for "tangible differentiation," craftsmanship selection transcends manufacturing to become a strategic tool connecting brand value with emotional engagement.

Complete Your Order and Enjoy Fast Shipping

Once your custom design is complete, submit your order, and we’ll get to work on crafting your piece with premium materials and expert distressing techniques. And don’t worry — we offer fast shipping, so you won’t have to wait long to receive your new custom streetwear.

Contact Us and Start Your Custom Journey Today!

If you're ready to design your own custom streetwear or have any questions, we’re here to help! Our customer service team is ready to ensure you get the best customization experience possible.

📞 Phone: [86-13428400973]

📧 Email: [info@chanjoye.com]

🌐 WhatsApp:[https://wa.me/8618025298509]

https://www.chanjoye.com/contact-us.htm

Click the link above to start designing your custom streetwear today. We can’t wait to help you express your bold style!