Inside the Factory: How We Create Premium Streetwear

- Share

- publisher

- 88

- Issue Time

- Jul 10,2025

Summary

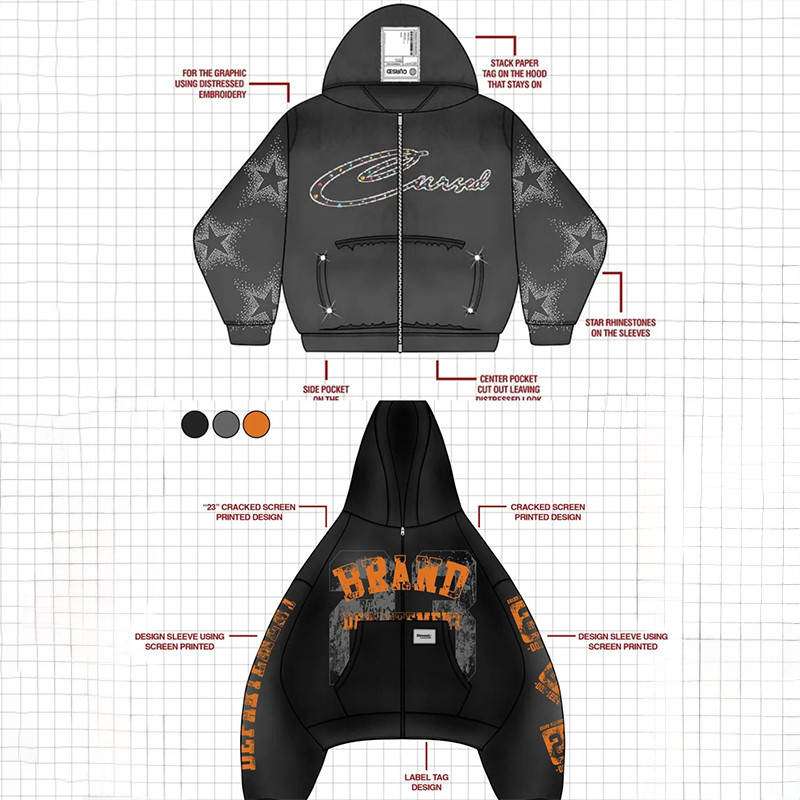

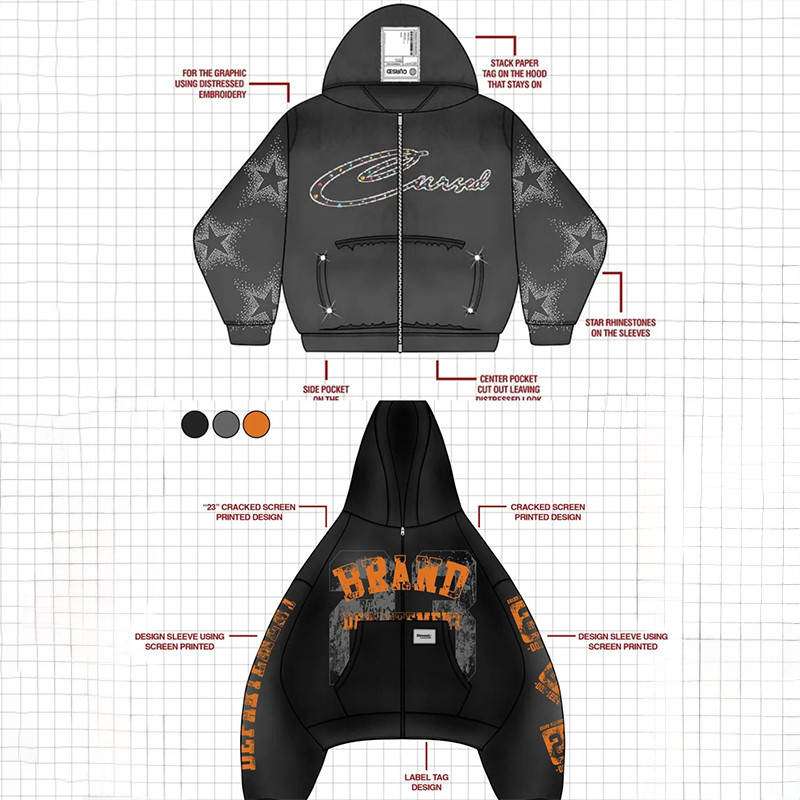

Chanjoye reveals premium streetwear creation: trend analysis → designer sketches → fabric tests → laser cutting → eco-printing → QC. Artisan-crafted details merge bold style with lasting quality.

When you turn heads on the street wearing a Chanjoye hoodie, have you ever wondered about the craftsmanship behind it? From premium fabric rolls to statement streetwear pieces, we pour obsessive attention into every stitch. Today, we invite you behind the scenes at Chanjoye's production facility to witness how elevated streetwear comes to life through our exacting manufacturing standards.

1. From Sketch to Digital Pattern: Where Art Meets Automation

A) Digital Pattern Making (The Blueprint Stage)

1)Our designers' hand-drawn sketches are scanned into 3D CAD systems (Gerber Accumark)

2)Laser digitizers convert physical samples into 0.1mm-precision digital patterns

3)AI checks for structural integrity (e.g., stress points on oversized sleeves)

B) The Prototyping Lab

1)Industrial cutting plotters output first samples in 22 minutes

2)Each prototype undergoes 7-point fit tests on adjustable mannequins

3)Version 4.7 is typical before approval (vs. industry average 2.3 versions)

2. Fabric Cutting: Where Precision Gets Physical

A) Intelligent Fabric Spreading System – Technology That Lets Fabric "Breathe"

1)Italy’s [Carù] fully automatic spreading machine unfurls fabric at 0.01m/s, with infrared sensors monitoring tension fluctuations in real time

2)Proprietary "Floating Spreading" technology: A negative-pressure suction table ensures fabric maintains <0.3% stretching deviation across 200-meter rolls

3)Each fabric roll undergoes "fingerprint scanning" upon arrival—database auto-loads shrinkage rate, color batch data (close-up of encrypted QR code on fabric label)

B) German TRUMPF Laser Cutters – Art Meets Extreme Heat

1)The 3000W [Trumpf TruLaser 5030] cuts through 50 layers of heavyweight sweatshirt fabric simultaneously, with edges sealed at precisely 217℃ (optimal melting point)

2)Dynamic path optimization reduces spacing between cut pieces to 1.2mm (vs. 5mm with traditional die-cutting, boosting material yield by 23%)

3)Real-time fume extraction filters particles down to 0.3μm (air quality display shows PM2.5=8μg/m³)

C) Robotic Sorting – The Future Is Here

1)Japan’s FANUC robotic arms with 3D vision identify and sort 1,800 irregular cut pieces/hour (slow-mo video shows gentle handling of lace mesh)

2)Each bundle features NFC chips for full traceability:

▸ Original fabric roll number

▸ Laser operator ID

▸ Timestamped completion (to the second)

3.Sewing Station: When Artisan Fingertips Meet AI Synapses

A) Intelligent Sewing Matrix – Algorithmic Aesthetics in Every Stitch

German [Dürkopp] 579 Smart Sewing Units operate in networked clusters, each equipped with:

✓ Submicron needle positioning (±0.05mm repeat accuracy)

✓ Real-time tension feedback (auto-adjusts 210 stitch tension combinations)

Proprietary "Memory Stitching" mode:

▸ Records veteran tailors' hand movements (including micro-tremors that create unique textures)

▸ Replicates "imperfect human touch" via industrial AI (vs. rigid mechanical stitching)

B) Ergonomic Workstations – The Invisible Battlefield

Each station features:

✓ Swiss [Hilti] anti-fatigue flooring (reduces muscle strain by 72%)

✓ Japanese [Omron] bio-sensing LED strips (auto-adjusts light temperature by operator's heart rate)

Behind-the-scenes footage: When crafting limited-edition hoodies, stations switch to "Artisan Mode":

▶ Slows conveyor speed by 30%

▶ Activates magnified laser projection

4. Final Inspection: 37-Step Quality Assurance Protocol

A) Precision Instrument Testing - Beyond Human Perception

Utilizes Japanese [Keyence] high-definition imaging systems for 3D scanning:

✓ Detects stitching deviations as subtle as 0.1mm

✓ UV verification ensures perfect print alignment

Each product maintains a digital quality with complete inspection records

B) Durability Testing - Simulating Real-World Wear

Professional equipment replicates daily use scenarios:

✓ 50-cycle wash tests (AATCC standard)

✓ Seam strength tests (2x industry requirements)

✓ Colorfastness verification (guaranteed fade resistance)

All test data uploaded to cloud-based quality management systems

Final Thoughts

At Chanjoye, we believe true streetwear soul lives not just in designs, but in the DNA of craftsmanship. From laser-cut precision to the human touch in every stitch, from 37 ruthless quality checks to fully traceable production records – these invisible obsessions transform casual clothing into enduring icons.

Complete Your Order and Enjoy Fast Shipping

Once your custom design is complete, submit your order, and we’ll get to work on crafting your piece with premium materials and expert distressing techniques. And don’t worry — we offer fast shipping, so you won’t have to wait long to receive your new custom streetwear.

Contact Us and Start Your Custom Journey Today!

If you're ready to design your own custom streetwear or have any questions, we’re here to help! Our customer service team is ready to ensure you get the best customization experience possible.

📞 Phone: [86-13428400973]

📧 Email: [info@chanjoye.com]

🌐 WhatsApp:[https://wa.me/8618025298509]

https://www.chanjoye.com/contact-us.htm

Click the link above to start designing your custom streetwear today. We can’t wait to help you express your bold style!